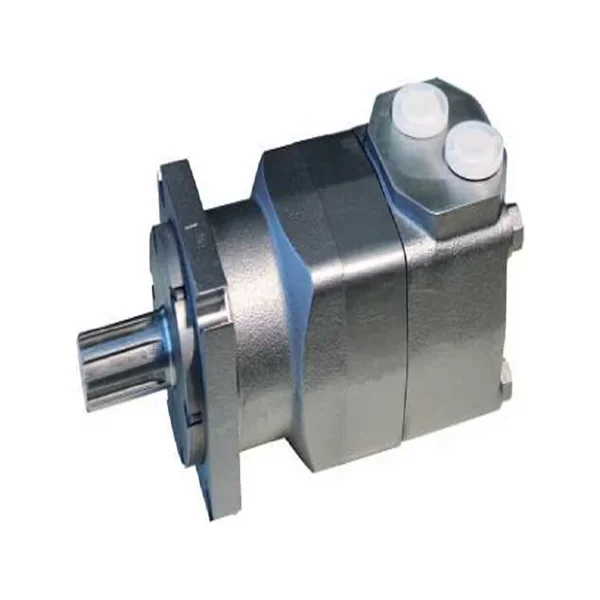

Hydraulic motors play a crucial role in powering various industrial machines across multiple sectors. As part of hydraulic systems, they convert fluid power into mechanical energy, offering high torque output and reliable performance. The use of hydraulic motors in industrial machinery is vital for efficiency and precision, especially in heavy-duty operations. In this article, we'll explore the top 5 applications of hydraulic motors in industrial machinery and discuss why they are preferred in these settings.

1. Construction Machinery

Hydraulic motors are widely used in construction machinery due to their ability to provide high torque in compact and efficient systems. Heavy-duty machines such as excavators, bulldozers, and wheel loaders rely on hydraulic motors to perform a variety of tasks that demand immense power and precision.

1. Excavators and Diggers

One of the applications of hydraulic motors is in excavators. Excavators are designed to dig, move, and remove earth, and they rely heavily on hydraulic motors to operate their tracks and attachments like the bucket or arm. The high torque provided by hydraulic motors allows for the lifting and digging of heavy loads, even in challenging terrains.

2. Bulldozers

Similarly, bulldozers use hydraulic motors to drive their tracks and power the blade mechanisms. These machines need to handle large amounts of soil, debris, or rock, making it critical that the hydraulic motors deliver consistent performance in tough conditions.

Hydraulic motors’ ability to provide smooth and continuous motion is essential for maintaining control over these heavy machines, making them indispensable in construction operations.

2. Agricultural Equipment

The agricultural industry benefits greatly from hydraulic motors because they offer the precision and power necessary to handle the demanding tasks on farms and fields. Hydraulic motors are a popular choice in agricultural machinery such as tractors, harvesters, and irrigation systems due to their reliability, efficiency, and ease of integration into various equipment.

1. Tractors and Plows

Hydraulic motors power several components of tractors and plows, including steering systems, PTO (power take-off) mechanisms, and the lift and lowering of attachments. The ability to control the torque output with hydraulic motors allows for smoother operations and better control, whether plowing, planting, or hauling heavy loads.

2. Harvesters and Combine Harvesters

In combine harvesters, hydraulic motors are used to power key systems, such as the cutting head and auger conveyors. The motors are essential in ensuring that crops are efficiently harvested and transported with minimal downtime. They offer the high torque required for the movement of large volumes of crops and materials, which is crucial during harvest season.

3. Irrigation Systems

Hydraulic motors are also widely employed in irrigation systems, especially for driving pumps that move water across large agricultural fields. These systems need to function reliably under variable conditions, and hydraulic motors provide the necessary power while maintaining efficiency and reducing fuel consumption.

3. Material Handling and Conveyor Systems

Material handling systems often incorporate hydraulic motors to provide reliable, high-torque motion for moving goods in factories, warehouses, or distribution centers. These systems require precision, reliability, and the ability to handle heavy loads—all of which are features provided by hydraulic motors.

1. Conveyor Belts

Conveyor systems, used in industries such as manufacturing, mining, and logistics, rely on hydraulic motors for driving belts and moving materials efficiently from one point to another. Hydraulic motors are ideal for these applications because they offer precise control over the conveyor speed and torque, even under load. This is crucial in environments where goods or raw materials are transported continuously, and failure can result in significant downtime.

2. Forklifts and Lift Trucks

Forklifts, essential for lifting and moving goods in warehouses, also use hydraulic motors for the lifting mechanism. The hydraulic system’s ability to provide high power in a compact form makes hydraulic motors perfect for lifting heavy pallets and materials with ease. The precision control available with hydraulic motors allows operators to carefully move loads in tight spaces without sacrificing speed or efficiency.

4. Mining Machinery

Mining operations are some of the most demanding industrial environments where machinery must withstand extreme conditions while providing reliable performance. Hydraulic motors are crucial in mining equipment, powering systems like drills, crushers, and loaders that require sustained torque and power.

1. Drilling Rigs

Mining drills and drilling rigs rely on hydraulic motors to provide the high torque needed to power the drill bit. Hydraulic motors give miners the ability to efficiently drill through hard rock and dense soil, often at significant depths. Their high power density ensures that drilling operations are performed with precision and minimal downtime, which is critical in the mining industry where speed and efficiency are key.

2. Rock Crushers

In the mining sector, rock crushers are used to break down large boulders into smaller, more manageable pieces. Hydraulic motors in these machines provide the necessary torque to crush rocks with high force. This allows for the continuous operation of crushers, ensuring a steady supply of materials for processing and transport.

3. Loaders and Haulers

Mining operations use loaders and haulers to move large quantities of material from extraction sites to processing facilities. Hydraulic motors are used in these vehicles to drive their wheels, lift and dump materials, and power various attachments. Their ability to deliver high torque at low speeds makes them ideal for moving heavy, dense materials through rough terrains and over long distances.

5. Automated Manufacturing and Robotics

Hydraulic motors are also commonly used in automated manufacturing systems and robotic machines, where precision, speed, and power are essential. Hydraulic motors in these applications provide accurate and controlled motion for tasks that require fine adjustments and repeatability.

1. Robotic Arms

In industries like automotive manufacturing and electronics assembly, robotic arms rely on hydraulic motors for precise movement and force control. Hydraulic systems are used to control the arms' movement along multiple axes, allowing them to perform tasks such as welding, assembly, painting, and packaging with accuracy.

2. Press Machines and Injection Molding

Hydraulic press machines are commonly used in metalworking and plastics processing. These machines require immense pressure to mold, form, or shape materials, and hydraulic motors provide the necessary power to operate the presses. The high torque and force output of hydraulic motors make them ideal for tasks that involve compressing or shaping materials at high pressures.

3. Assembly Lines

In automated assembly lines, hydraulic motors are used to power components like conveyors, lifting platforms, and material handling equipment. The precise control over movement and torque provided by hydraulic motors ensures that each stage of the assembly process is executed correctly and efficiently.

Conclusion

Hydraulic motors are essential components in the operation of industrial machinery, providing the power, precision, and durability required for a wide range of applications. From construction machinery to agricultural equipment, material handling systems, mining machinery, and automated manufacturing processes, hydraulic motors are indispensable in ensuring smooth, reliable operations in industries worldwide.

At Shanghai AJA Technology Co., Ltd., we are committed to providing high-quality products and excellent customer service. Whether you need assistance with hydraulic motor cleaning or any other hydraulic component-related queries, our knowledgeable staff is ready to help.

Welcome to inquiry if you need to know more about hydraulic motors details or order wholesale.