In the ever-evolving world of construction materials, brick and tile manufacturing is experiencing a significant transformation—driven not just by shifting market demands, but also by innovations in production machinery. Among the key technologies leading this change is the compact vacuum extruder, a modern solution that is reshaping how manufacturers approach efficiency, quality, and scalability.

Traditionally, the production of clay bricks and tiles required large-scale, energy-intensive equipment that dominated factory floors and demanded significant infrastructure. Today, compact vacuum extruders are proving that high-quality output doesn’t have to come at the cost of space, energy, or operational complexity. As a result, they are becoming an indispensable tool in both small-scale operations and large-scale modernization efforts.

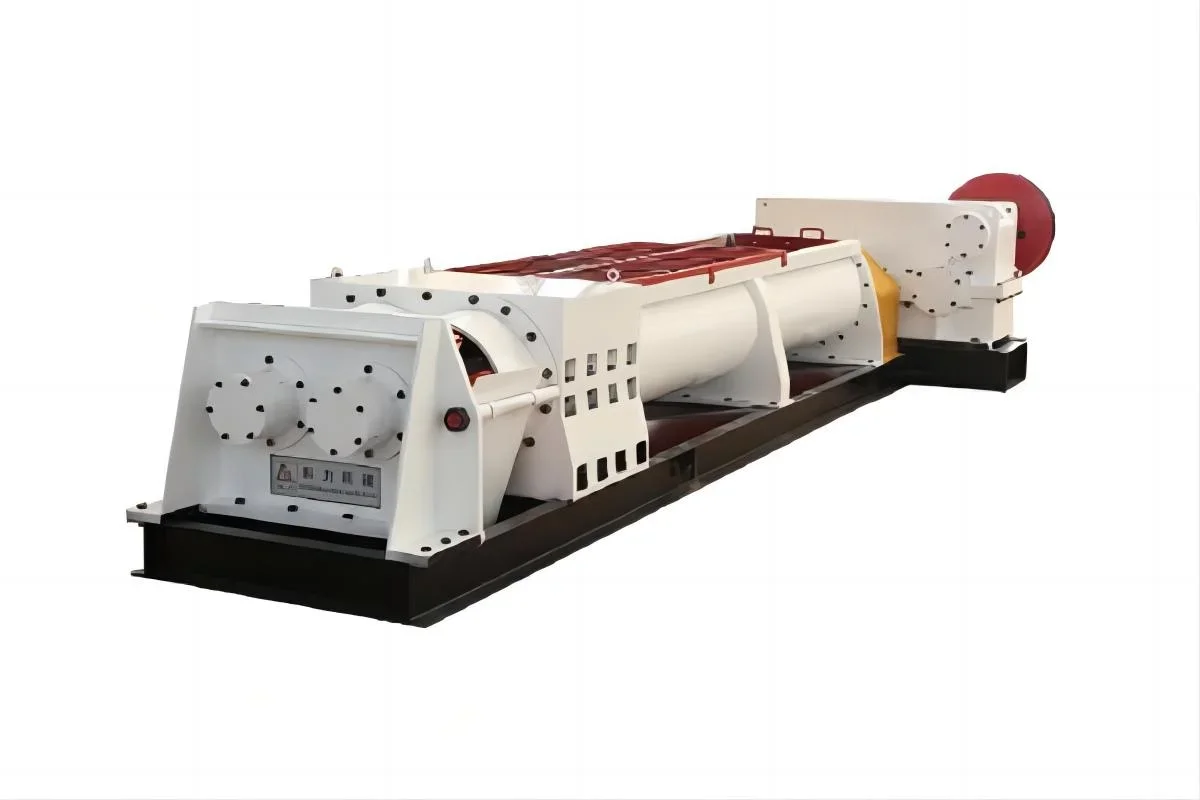

Understanding the Compact Vacuum Extruder

To appreciate the impact of this equipment, it’s important to understand its function. A vacuum extruder is a machine designed to shape plastic clay into uniform forms—typically bricks or tiles—through a process of de-airing and extrusion. It does this by using a vacuum system to remove air pockets from the clay, ensuring a denser, more consistent product. The de-aired clay is then forced through a die to produce continuous strips that are cut into individual units.

What makes https://www.yxkelijixie.com/Compact-vacuum-extruder.html unique is their optimized design. Unlike traditional extruders, which can be large, segmented, and space-consuming, compact models integrate all major functions—feeding, mixing, de-airing, and extrusion—into a single, streamlined unit. These machines are often smaller in footprint, easier to install, and more energy-efficient, while still delivering exceptional output.

Advantages of Compact Vacuum Extruders in Brick and Tile Manufacturing

1. Enhanced Space Efficiency

One of the most immediate benefits is the small footprint of the machinery. Compact extruders are especially suitable for brick and tile plants that have limited floor space or are located in urban or remote areas where expansion is difficult. Their ability to fit into tight production areas makes them ideal for decentralized manufacturing units or satellite facilities.

2. Lower Energy Consumption

Compact extruders are often built with modern motors, gearboxes, and energy-saving control systems that significantly reduce power consumption. With rising energy costs becoming a burden on manufacturers globally, the use of a compact vacuum extruder can result in notable operational savings over time.

3. Improved Clay Quality and Product Uniformity

The vacuum chamber in these machines plays a vital role in removing entrapped air from the clay mixture. This not only improves the density and strength of the end product but also reduces the risk of cracking or warping during drying and firing. Uniform extrusion ensures that each brick or tile maintains a consistent size and shape, enhancing overall quality control.

4. Simplified Maintenance and Operation

Compact vacuum extruders are designed for ease of use. Many come with intuitive control systems, modular parts for easy replacement, and fewer moving components than traditional systems. This simplifies maintenance routines and reduces downtime, allowing for more continuous operation.

5. Adaptability Across Clay Compositions

Another strength of these machines lies in their ability to handle a wide variety of clay compositions—whether highly plastic clays or mixes with sand and additives. This versatility makes compact vacuum extruders suitable for manufacturers producing multiple product lines, from standard red bricks to glazed roofing tiles or ceramic floor tiles.

Applications Across Different Scales of Manufacturing

Whether it’s a small rural brick-making plant or a large urban tile factory, compact vacuum extruders are proving valuable at multiple scales of production.

For Small to Medium Enterprises (SMEs): The compact design and lower upfront investment make these extruders accessible to smaller manufacturers. This opens the door for local production units to deliver high-quality bricks and tiles without the need for large factories.

For Large Manufacturers: Many large companies are using compact extruders for specialized product lines or as auxiliary machines that complement their main production systems. This allows for more flexibility in product development and smaller batch runs without interrupting the primary workflow.

Sustainability and Environmental Impact

Sustainability is increasingly at the core of modern manufacturing strategies. Compact vacuum extruders support this shift in several ways:

a. Energy Efficiency: Reduced power usage translates to lower greenhouse gas emissions.

b. Less Material Waste: Precise shaping reduces off-cuts and defective pieces.

c. Reduced Carbon Footprint: Localized production enabled by compact machines helps cut down on transportation emissions.

Additionally, the ability to use locally sourced clay materials with minimal processing helps promote environmentally responsible sourcing practices.

Conclusion

The compact vacuum extruder is more than just a piece of machinery—it is a strategic asset for brick and tile manufacturers looking to modernize operations without sacrificing quality or space. From improving product consistency and energy savings to enabling flexible, scalable production, this technology is a game-changer for the industry.

As construction standards evolve and the demand for sustainable, high-quality building materials continues to grow, compact vacuum extruders are set to play a central role in shaping the future of clay product manufacturing.

Keli Machine Compact Vacuum Extruder: A Reliable Solution for Brick Making