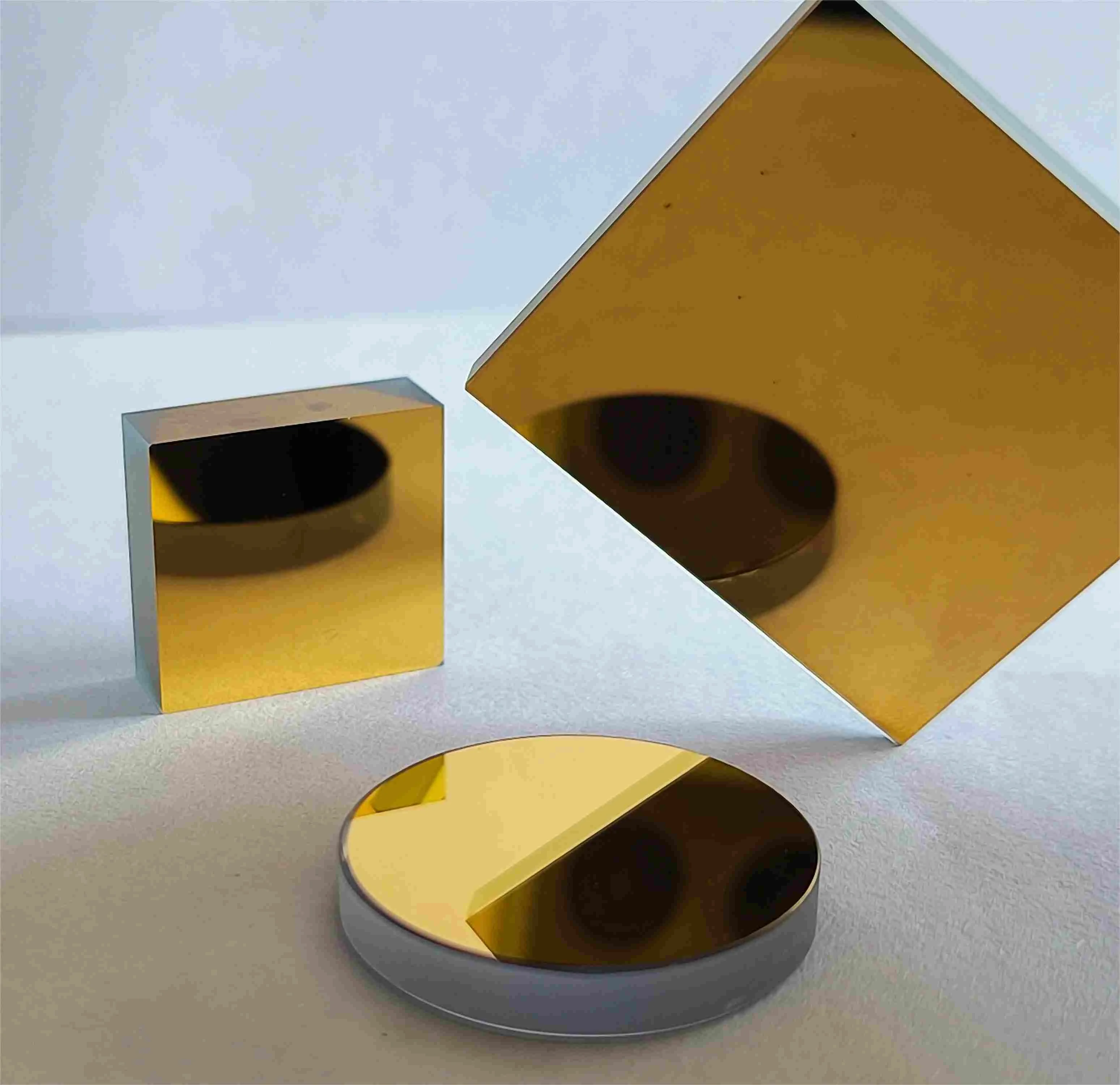

In the realm of optics and reflective surfaces, metal mirror coatings play a crucial role in enhancing performance and durability. At Yushen Optoelectronics, we specialize in high-quality metal mirrors, including gold (Au), aluminum (Al), and silver (Ag) coatings, designed for various applications. This comprehensive overview will delve into the key aspects of metal mirror coatings, their types, applications, and essential parameters that define their effectiveness.

What Are Metal Mirror Coatings?

Metal mirror coatings are thin layers of metal applied to a substrate to create highly reflective surfaces. These coatings are essential in numerous optical applications, including telescopes, lasers, and solar panels. The primary metals used for these coatings are aluminum, silver, and gold, each offering unique properties that make them suitable for specific uses.

Key Types of Metal Mirror Coatings:

1. Gold (Au) Mirrors: Known for their excellent reflectivity in the infrared spectrum, gold mirrors are ideal for applications requiring high performance in thermal imaging and laser optics.

2. Aluminum (Al) Mirrors: Aluminum coatings provide broad-spectrum reflectivity and are commonly used in visible light applications. They are cost-effective and widely utilized in various optical devices.

3. Silver (Ag) Mirrors: Silver mirrors offer the highest reflectivity across a wide range of wavelengths, making them suitable for high-performance optical systems.

Important Parameters of Metal Mirror Coatings

When selecting metal mirror coatings, several critical parameters must be considered:

- Reflectivity: This is the most important performance indicator, determining the mirror's ability to reflect light effectively. High reflectivity is essential for maximizing efficiency in optical systems.

- Spectral Range: The spectral range refers to the range of wavelengths that a mirror can effectively reflect. Different metals perform better at different wavelengths; for example, gold excels in the infrared range while silver is superior in visible light.

- Angle Tolerance: This parameter defines how well a mirror maintains its reflective properties at various angles of incidence. A wide angle tolerance is beneficial for applications where light may hit the mirror at different angles.

- Environmental Stability: Metal mirrors must withstand various environmental conditions without degrading. Factors such as humidity, temperature fluctuations, and exposure to chemicals can impact their performance over time.

Applications of Metal Mirror Coatings

Metal mirror coatings find extensive use across multiple industries due to their versatile properties:

- Optical Devices: Used in telescopes, microscopes, and cameras to enhance image quality through improved light reflection.

- Solar Energy: Employed in solar concentrators to maximize sunlight capture and improve energy efficiency.

- Laser Systems: Essential for directing laser beams accurately in industrial cutting and medical applications.

- Automotive: Used in headlights and rear-view mirrors to enhance visibility and safety.

Conclusion

Metal mirror coatings are integral to modern optical systems, providing enhanced reflectivity and durability across various applications. At Yushen Optoelectronics, we offer a range of high-quality metal mirrors tailored to meet your specific needs. By understanding the key parameters and applications of metal mirror coatings, you can make informed decisions that enhance your projects' performance. If you have any questions or need assistance with our products, feel free to reach out!