In the fast-paced world of industrial cleaning, efficiency, effectiveness, and safety are paramount. Traditional cleaning methods often fall short in meeting these demands, leading to the exploration of innovative technologies. One such technology that has gained significant traction is the digital ultrasonic generator. This article delves into the benefits of using a digital ultrasonic generator in industrial cleaning processes, highlighting its advantages, applications, and the science behind its effectiveness.

Understanding Ultrasonic Cleaning Technology

Before exploring the benefits, it’s essential to understand how ultrasonic cleaning works. Ultrasonic cleaning utilizes high-frequency sound waves, typically between 20 kHz and 400 kHz, to create millions of microscopic bubbles in a cleaning solution. This process, known as cavitation, occurs when the sound waves pass through the liquid, causing the bubbles to form and implode. The implosion generates powerful shock waves that dislodge contaminants from surfaces, making ultrasonic cleaning highly effective for various applications.

The Role of Digital Ultrasonic Generators

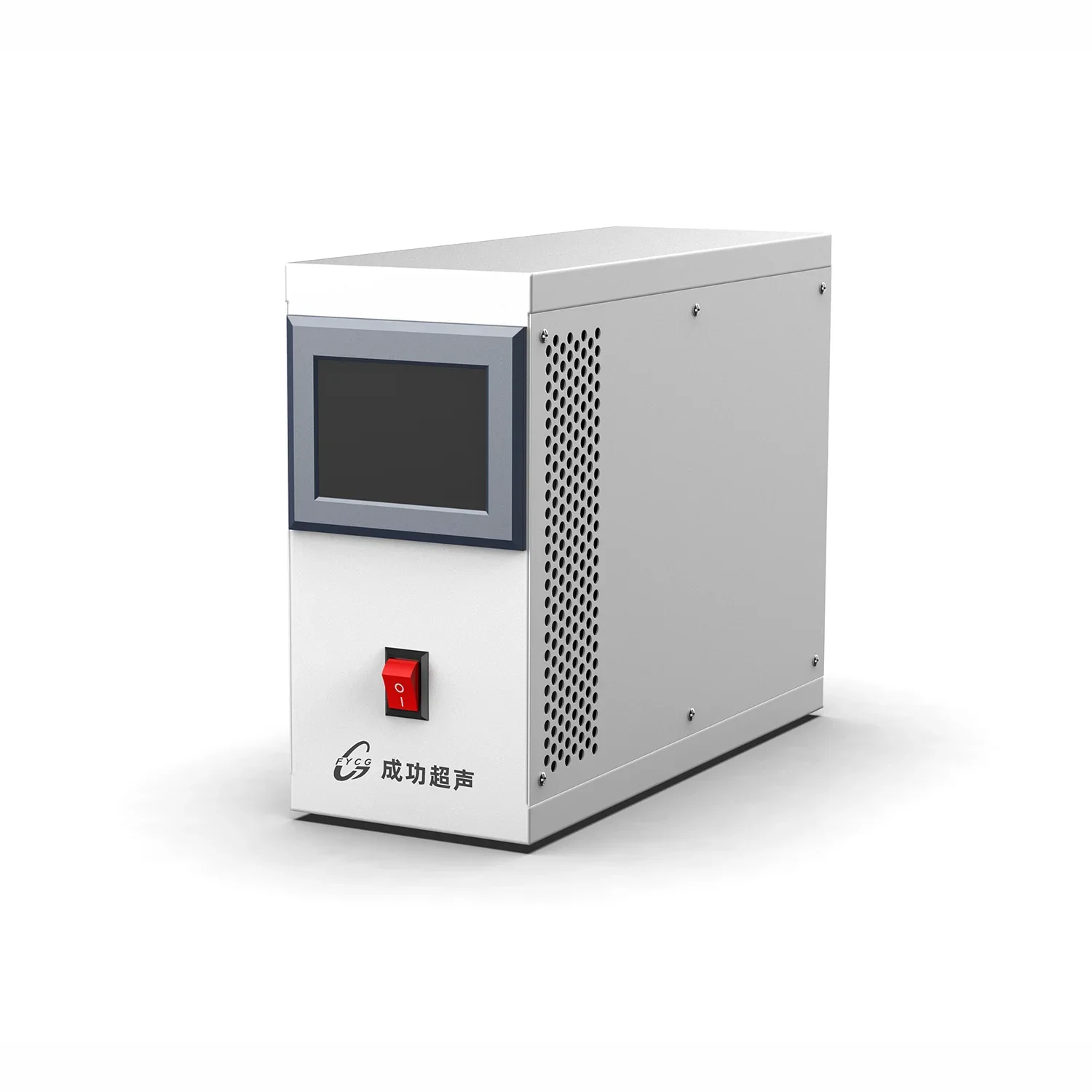

Digital ultrasonic generators are advanced devices that produce ultrasonic waves with precision and control. Unlike traditional ultrasonic generators, digital models offer enhanced features such as adjustable frequency, power settings, and digital displays for monitoring performance. These improvements make digital ultrasonic generators particularly suitable for industrial cleaning processes, where customization and reliability are crucial.

Benefits of Using Digital Ultrasonic Generators in Industrial Cleaning

1. Superior Cleaning Efficiency

One of the most significant advantages of using a digital ultrasonic generator is its superior cleaning efficiency. The cavitation process allows for thorough cleaning of complex geometries and hard-to-reach areas that traditional cleaning methods often miss. This capability is especially beneficial for cleaning intricate parts, such as those found in the automotive, aerospace, and medical industries.

2. Time-Saving

In industrial settings, time is money. Digital ultrasonic generators can significantly reduce cleaning times compared to manual or traditional cleaning methods. The ultrasonic cleaning process typically takes only a few minutes, depending on the level of contamination and the material being cleaned. This efficiency allows businesses to streamline their operations, reduce downtime, and increase productivity.

3. Environmentally Friendly

With growing concerns about environmental sustainability, many industries are seeking eco-friendly cleaning solutions. Digital ultrasonic generators use water-based cleaning solutions that are biodegradable and non-toxic. This reduces the need for harsh chemicals, minimizing environmental impact and ensuring compliance with regulations. Additionally, the efficient use of cleaning solutions means less waste, further contributing to sustainability efforts.

4. Consistent Results

Consistency is critical in industrial cleaning processes. Digital ultrasonic generators provide uniform cleaning results due to their precise control over frequency and power settings. This consistency ensures that every item cleaned meets the required standards, reducing the risk of defects and enhancing product quality. Industries such as electronics and pharmaceuticals, where cleanliness is paramount, benefit greatly from this reliability.

5. Versatility

Digital ultrasonic generators are incredibly versatile and can be used to clean a wide range of materials, including metals, plastics, glass, and ceramics. This adaptability makes them suitable for various applications, from cleaning delicate electronic components to removing grease and grime from industrial machinery. The ability to switch between different cleaning solutions and settings further enhances their versatility.

6. Reduced Labor Costs

The automation of cleaning processes through digital ultrasonic generators can lead to significant labor cost savings. With the ability to clean multiple items simultaneously and the reduced need for manual scrubbing, businesses can allocate their workforce more efficiently. This not only lowers labor costs but also allows employees to focus on more value-added tasks, improving overall operational efficiency.

7. Enhanced Safety

Safety is a top priority in industrial environments. Traditional cleaning methods often involve the use of hazardous chemicals and manual handling of heavy equipment, which can pose risks to workers. Digital ultrasonic generators, on the other hand, minimize these risks by reducing the need for harsh chemicals and manual labor. Additionally, the enclosed cleaning tanks used in ultrasonic cleaning processes help contain any potential hazards, further enhancing workplace safety.

8. Improved Equipment Longevity

Regular cleaning of industrial equipment is essential for maintaining performance and extending lifespan. Digital ultrasonic generators effectively remove contaminants that can cause wear and tear on machinery, leading to improved equipment longevity. By investing in ultrasonic cleaning technology, businesses can reduce maintenance costs and downtime associated with equipment failure.

9. Customization and Control

Digital ultrasonic generators offer advanced features that allow for customization and control over the cleaning process. Operators can adjust frequency, power, and cleaning time to suit specific cleaning requirements. This level of control ensures optimal cleaning results and allows for the adaptation of cleaning processes to accommodate different materials and contaminants.

10. Cost-Effectiveness

While the initial investment in a digital ultrasonic generator may seem significant, the long-term cost savings can be substantial. The combination of reduced cleaning times, lower labor costs, and improved equipment longevity contributes to a favorable return on investment. Additionally, the eco-friendly nature of ultrasonic cleaning can lead to savings on waste disposal and compliance costs.

Applications of Digital Ultrasonic Generators in Industrial Cleaning

Digital ultrasonic generators find applications across various industries, including:

1. Automotive: Cleaning engine parts, fuel injectors, and carburetors.

2. Aerospace: Removing contaminants from aircraft components and tools.

3. Medical: Sterilizing surgical instruments and cleaning dental tools.

4. Electronics: Cleaning circuit boards and delicate electronic components.

5. Manufacturing: Degreasing and cleaning machinery and tools.

Conclusion

The benefits of using a digital ultrasonic generator in industrial cleaning processes are clear. From superior cleaning efficiency and time savings to environmental sustainability and enhanced safety, these advanced devices offer a comprehensive solution for modern industrial cleaning challenges. As industries continue to seek innovative ways to improve their operations, digital ultrasonic generators stand out as a reliable and effective choice. By investing in this technology, businesses can enhance their cleaning processes, improve product quality, and ultimately achieve greater operational success.

Hangzhou Successful Ultrasound Equipment Co., Ltd. is a domestic professional manufacturer engaged in ultrasonic application research, development and production of high-power ultrasonic transducers, and is a national high-tech enterprise. The company's main products include transducers, ultrasonic drive power supplies, etc. As the core and key components of power supplies, these products are widely used in sonochemistry, plastic welding, metal welding, rubber cutting, non-woven fabric welding and other ultrasonic application industries.

If you are interested in our digital ultrasonic generator, please contact us. We will provide you with digital ultrasonic generator solutions.