In modern construction, manufacturing, and design, perforated metal sheets have become a versatile and essential material. Whether you’re an architect, engineer, or contractor, understanding how to effectively use perforated metal sheets can significantly enhance your projects. This article explores how you can supercharge your projects with perforated metal sheet, focusing on its benefits, types, applications, and practical tips for selection and use.

Understanding Perforated Metal Sheet and Its Advantages

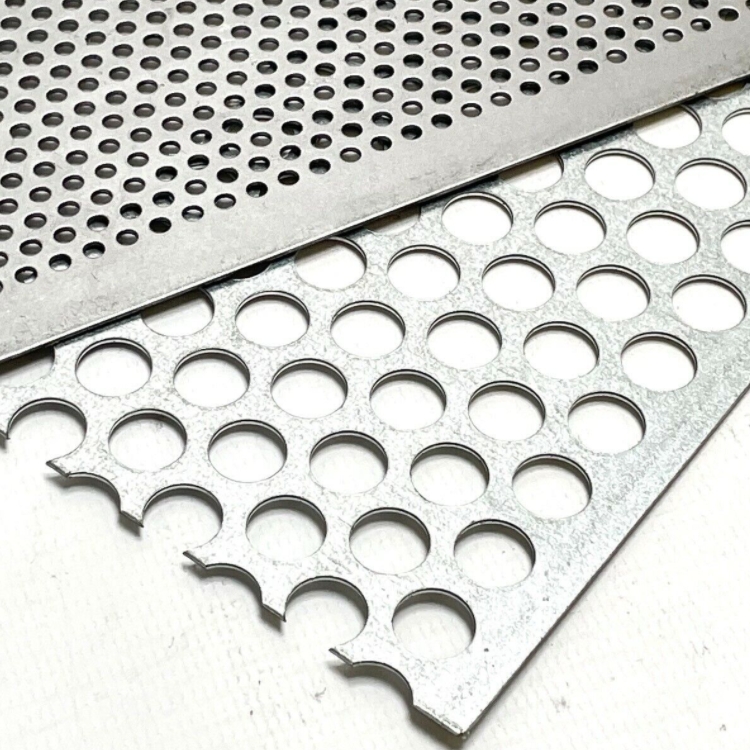

Perforated metal sheet is a type of sheet metal that has been mechanically stamped or punched with a variety of hole patterns. The perforations vary in size, shape, and distribution depending on the intended application. These sheets are produced from various metals such as stainless steel, aluminum, copper, and galvanized steel, making them adaptable for many environments.

Enhanced Functionality Through Perforation

One of the primary advantages of Perforated Metal Sheet is its ability to combine strength with permeability. The perforations allow airflow, light transmission, and drainage while maintaining structural integrity. This makes perforated sheets ideal for filtration, ventilation, and acoustic control applications.

Improved Aesthetics and Design Flexibility

Perforated metal sheets are increasingly popular in architectural design because of their ability to add visual interest while serving functional purposes. Different hole patterns and metals can create unique façades, sunscreens, and decorative elements that stand out.

Key Applications Where Perforated Metal Sheet Supercharges Performance

Potential of Perforated Sheets:

Architectural and Facade Solutions

Perforated metal sheets offer an elegant solution for building façades, sunshades, and cladding. Their light permeability reduces heat gain while allowing natural light to enter, improving energy efficiency. Moreover, they provide privacy without completely blocking visibility.

Acoustic Panels and Noise Control

In environments like auditoriums, offices, and factories, controlling noise is critical. Perforated metal sheets, when combined with sound-absorbing materials, create effective acoustic panels. The perforations allow sound waves to pass through and be absorbed, reducing echo and noise pollution.

Industrial and Filtration Uses

Perforated metal sheets are widely used in industrial settings for filtration, screening, and protective covers. Their durability and corrosion resistance make them perfect for harsh environments where solid sheets would fail.

Furniture and Interior Design

Designers are incorporating perforated metal sheets in furniture, partitions, and interior décor to add modern textures and patterns. They provide functional benefits like ventilation in cabinets while enhancing aesthetics.

How to Select the Right Perforated Metal Sheet for Your Project

Choosing the correct perforated metal sheet is essential to supercharge your projects. Several factors must be considered to ensure optimal performance and longevity.

Material Selection

The choice of metal depends on the application environment. Stainless steel is ideal for corrosion resistance and strength, aluminum for lightweight needs, and galvanized steel for cost-effectiveness in outdoor settings.

Hole Size and Pattern

The size, shape, and pattern of the perforations directly affect the sheet’s functionality. Smaller holes are better for fine filtration and sound absorption, while larger holes provide more ventilation and light. Common patterns include round, square, slotted, and decorative shapes.

Thickness and Strength

The gauge or thickness of the sheet influences its load-bearing capacity and durability. Projects requiring structural support need thicker sheets, whereas decorative uses can accommodate thinner materials.

Finish and Coating

Surface treatment such as powder coating, anodizing, or galvanizing enhances resistance to weather and wear, extending the lifespan of the metal sheet.

Practical Tips to Maximize the Impact of Perforated Metal Sheets

Proper planning and installation are vital to harnessing the full benefits of perforated metal sheets.

Designing for Purpose

Begin by clearly defining the functional goals—whether for ventilation, aesthetics, noise control, or protection. Tailor the perforation pattern and metal choice accordingly.

Collaborate with Experienced Suppliers

Work with trusted manufacturers who offer customization options and technical support. Quality control during production is crucial for precision and consistency.

Installation Considerations

Ensure that mounting and support structures accommodate the metal sheet’s weight and allow for thermal expansion. Proper fastening prevents deformation and maintains alignment.

Maintenance for Longevity

Regular cleaning and inspection prevent buildup of debris in perforations and address corrosion issues early. Choose coatings suited for your environment to reduce maintenance needs.

Emerging Trends and Innovations in Perforated Metal Sheets

New technologies are expanding the applications and capabilities of perforated metal sheets.

Advanced Laser Cutting Techniques

Laser perforation allows intricate and precise patterns beyond traditional punching methods. This enhances design possibilities for architects and designers.

Integration with Smart Technologies

Embedding sensors and smart materials within perforated metal sheets is an emerging trend, enabling dynamic façades that respond to environmental changes.

Sustainable and Recyclable Materials

Eco-friendly production methods and recyclable metals align perforated metal sheets with green building standards.

Conclusion: How Can You Supercharge Your Projects With Perforated Metal Sheet?

By integrating perforated metal sheets into your projects, you unlock a blend of strength, versatility, and design freedom that few materials offer. Whether enhancing building façades, improving acoustic environments, or adding aesthetic appeal, perforated metal sheets can elevate the performance and impact of your work.

To truly supercharge your projects with perforated metal sheet, focus on selecting the right material, pattern, and thickness tailored to your needs. Collaborate with expert suppliers, pay attention to installation, and stay updated on innovations to maximize the benefits.

With these strategies, perforated metal sheets become more than just building materials—they become key components that drive efficiency, functionality, and style in your projects.

For more insightful articles related to this topic, feel free to visit: wutdawut